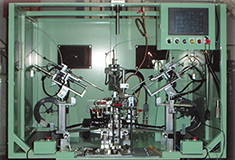

MATERIAL DIVISION BRAZING EQUIPMENT

N-500(DE SAVER)

No Pilot Flame.

DE Saver is the product featuring "COST-DOWN" "SAFETY"

and "EASY OPERATION" for gas welding and gas brazing

operation.

(Valveless torch is optional)

Using DE Saver, what an operator has to do is only to ignite the torch at beginning of gas welding or brazing operation and to hang it to the hanger for extinguishing the torch after the operation. There are no troublesome valve adjustments of the torch. The ignition to the torch can be done by only spark igniter and saves the gas consumption.

The gas discharge will stop within 2.0 seconds, when the torch fall off from the hanger or the device falls down caused by emergency disasters such as an earthquake or an accident. Moreover, the gas discharge will also inevitably stop, when a power supply is cut off. Then after an electric power is restored, the gas does not discharged, as the solenoid valves are locked with "FULL INTERLOCK" system.

Because of no pilot flame, there is no choke at pilot nozzle and the ignition method is spark, there is no influence by fan or spot cooler.

- SPECIFICATION

-

The table can be scrolled horizontally.

Rating voltage AC 100V/230V Outer dimension 120( w )×116( D )×271( H ) mm Weight Approx. 4kg Ignition method Spark ignition Flame detection Flame rod Connecting method Hose joint/Flame nut (M16-P15)

N-700

By switching with a foot switch

It can easily switch between two flames of strong flame and weak flame, contributing to improvement of working efficiency.

(Valveless torch is optional)

N-1000

A digital flow meter is built in, and it is the best of your work management and quality control. The introducing spark igniter save gas cost, and the ignition is very well. The gas is automatically turn off safety even if the torch comes off from the lever by introducing the frame sensor.

Valve-less torch

Lightweight is achieved by losing the valve from the torch, and worker's working environment is improved.

ELECTRON CONTROL MASS FLOW VALUE BUILT-IN

DIGITALDISPLAY FOR GAS FLOW RATE.

GAS SAVER for the new age has digital display of gas flow rate.

For SAFETY, COST DOWN and OPERATION CONTROL of gas brazing operations.

It is easy to prepare the brazing operation manual, which was not possible.

- TO SAVE GAS CONSUMPTION

- No pilot flame.

- TO BE SAFE

- When the torch fall off from the lever (torch hanger), gas stops automatically.

- TO HAVE HIGH FUNCTION

- Gas flow rate of each low flame and high flame can be selected by a foot switch.

- TO CONTROL

- As gas flow rates are displayed by digital figures, it is easy to control the brazing operation.

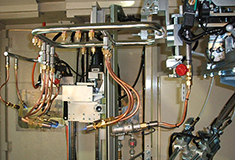

VAPOUR TANK

- ADVANTAGES

- ・The inside of Vapour Tank S-21 is made by stainless steel. Therefore, stable brazing can be obtained without deterioration of using flux and discoloring by rust.

・Vapour Tank S-21 supplies the stable Flux by mixing fuel gas and Vapour Flux.

・Vapour Tank S-21 is strong and has high performance against pressure. It is designed to operate and maintenance simply.

・Vapour Flux is solvent base with the methanol. Please keep away from heat or flame.

・When water sealed safety check is furnished in the gas line, Vapour Flux tends to be crystallized with water and clogged in the Vapour Tank.

・To infuse flux to Vapour Tank, use Spare Tank is convenient and recommendation.

- TANK SPECIFICATION

-

The table can be scrolled horizontally.

Bottom plate 8.0mm/t Body trunk plate 5.5mm/t Mirror plate part 6.0mm/t Flange Forging Gasket Sparkling polyethylene

- Spare Tank example

-

-

Vapour Hose

(Use For Vapour Flux Only)ø9.5 ø6.3

Stainless type Vapour Tank

※ The bottom is a vapor flux vaporization tank.The upper part is a spare tank.

Because of the rust does not occur inside the tank, not only flux does not deteriorate and cleaning decrease, also maintenance decreases.

In the photograph, you can see a spare tank S-type made of metal.

It is possible to set up exchange for cans (A-type) and plastic bottles (P-type) as it is as a spare tank.

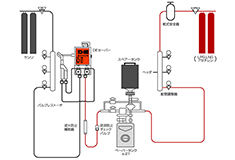

V. Auto Tank

As Vapour Flux is supplied from supplementary tank as much as it is used. Level of Vapour Flux is kept fixed level always.

Level is kept fixed by controlling 2 pcs. of valves which are attached between supplementary tank and Vapour Tank. Valve control is operated with built-in control unit. One cycle operation of valve can supply about 100cc of Vapour Flux into Vapour Tank. If the temperature is less likely to vaporize flux low, it is also possible to use put a hot water around the tank. (High water type) ※ The photo will be high water type.

- SPECIAL FEATURES

- ・Since stable Vapour Flux evaporation can be obtained with Vapour Flux fixed level function, heating conditions are stable and good brazing can be performed.

・Since sensor is not used, there is no adjustment place.

・As quantity of Vapour Flux can be kept a little in Vapour Tank, staying Vapour Flux is decreased in Vapour Tank. Therefore, aging of Vapour Flux can be prevented and stable evaporation can be obtained.

・Between Vapour Tank and supplementary tank is cut off always with 2 pcs. of valve controls, there is no way that Vapour Flux in Vapour Tank flows backward to supplementary tank.

・It is not necessary to add Vapour Flux during operation, since supplementary tank has large capacity.

・As Vapour Tank and supplementary tank are made of stainless steel, aging Vapour Flux is prevented and it is economical.

・Maximum used quantity of Vapour Flux per hour can be selected with switch, however, under maximum quantity, it corresponds automatically according to used quantity.

・Remained quantity of Vapour Flux in supplementary tank can be seen with level gauge easily.

・ON/OFF control signals from outside can be input.

- SPECIFICATION

-

The table can be scrolled horizontally.

Power source AC 100V (±10%) Outer dimension 250(W)x500(D)x946(H) Supplementary tank Tank capacity 3.0L

- PRODUCT

MACHINERY DEPARTMENT

MATERIAL DIVISION