MACHINERY DEPARTMENT AUTOMATIC BRAZING MACHINE VARIOUS SERIES

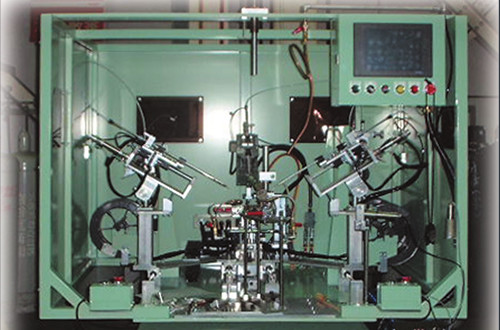

Model HS

- Single Station Machine

- Large HMI Touch Panel

- Flotron Intelligent Gas Controller (for full control of combustion gas mix ratio and delivery)

- Fully customizable fixture and burner design

- Options include:

- Multistage heating (multiple flame settings, as well as heating positions, within each cycle)

-

- Wire Feeding System

- Vapour Flux System (vaporized flux in flame)

- Optimum Heating System (fixture temperature variation compensation tool)

- Automatic burner ignition

- Post-brazing air and/or water cooling of parts

- Fixture is stationary at operator position

- Burner unit (and wire feeder, if applicable) advances to the fixture for brazing and returns to home position at the end of each cycle

- Excellent introductory system, or for lower-volume applications

- A second set of fixture and burner unit can be added to increase throughput (Model HW)

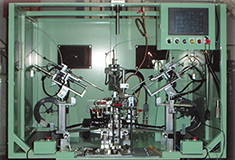

Model HS-T

- Two-station machine with 180° rotating table

- Large HMI Touch Panel

- Flotron Intelligent Gas Controller (for full control of combustion gas mix ratio and delivery)

- Fully customizable fixture and burner design

- Options include:

- Multistage heating (multiple flame settings, as well as heating positions, within each cycle)

-

- Wire Feeding System

- Vapour Flux System (vaporized flux in flame)

- Optimum Heating System (fixture temperature variation compensation tool)

- Automatic burner ignition

- Post-brazing air and/or water cooling of parts

- Table Rotates 180°

- Operator loads-unloads a part from one fixture while a part is being brazed in the fixture on the other side of the table

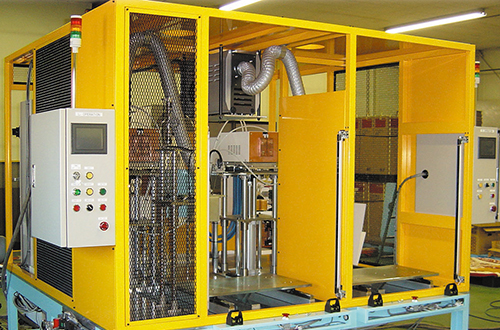

Model T

- Indexing Table Type (2-16 station capacity)

- CKD Absodex table rotation unit

- Large HMI Touch Panel

- Flotron Intelligent Gas Controller (for full control of combustion gas mix ratio and delivery)

- Fully customizable fixture and burner design

- Options include:

-

- Multistage heating (multiple flame settings, as well as heating positions, within each cycle)

- Multiple heating stations via index table (preheating and brazing)

- Wire Feeding System

- Vapour Flux System (vaporized flux in flame)

- Paste flux application system

- Optimum Heating System (fixture temperature variation compensation tool)

- Automatic burner ignition

- Post-brazing air and/or water cooling of parts

- Table indexes by cycle time

- Operator loads/unloads parts at the operator station as other fixtures travel to each station on the index table

- Excellent design for high volume production

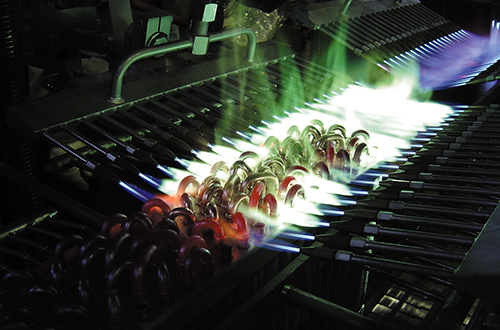

Model C

- Conveyor type brazing machine

- Used for return brazing to hear exchanger hairpins

- Bottom support slat, chain drive top tube sheet support, bottom support, palletized designs, etc. available

- Large HMI Touch Panel

- Flotron Intelligent Gas Controller (for full control of combustion gas mix ration and delivery)

- Fully customizable fixture and burner design

- Options include:

- Automated burner position adjustment

- Automated burner angular adjustment

- Vapour Flux System (vaporized flux in flame)

- Automatic burner ignition

- Post-brazing air cooling of parts

- Parts are loaded either manually or automatically on the conveyor and pass through the machine for brazing. All braze settings are customizable and stored in the PLC, accessible via the HMI for quick and easy changeover (burner position, conveyor speed, combustion gas mix ratio, et al.)

- Parts are unloaded either manually or automatically at the opposite end of the machine

Model R

- Robotic brazing machine

- Robot carries burner manifold (wire feeder and Vapour flux nozzles where applicable)

- Highly versatile system for brazing multiple joints on a single work piece, or single joints on a work piece with complex or difficult braze joint orientation

- Fixture positioning can also be automated to work in conjunction with robot positioning

- Large HMI Touch Panel

- Flotron Intelligent Gas Controller (for full control of combustion gas mix ratio and delivery)

- Fully customizable fixture and burner design

- Options include:

- Automated burner position adjustment

- Vapour Flux System (vaporized flux in flame)

- Paste fluxing system

- Wire feeding system

- Automatic burner ignition

- Post-brazing air and cooling of parts

- Parts are loaded in the fixture. The robot brazes the part, and the part is removed from the fixture at the end of the cycle

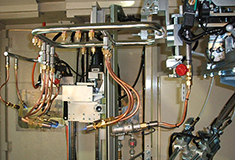

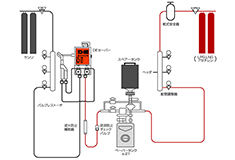

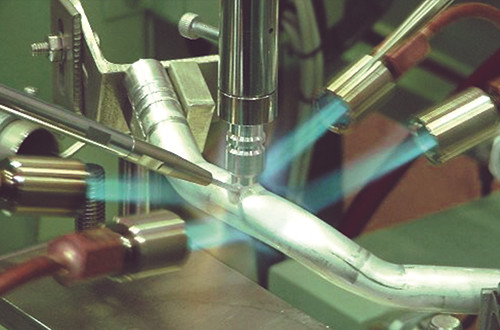

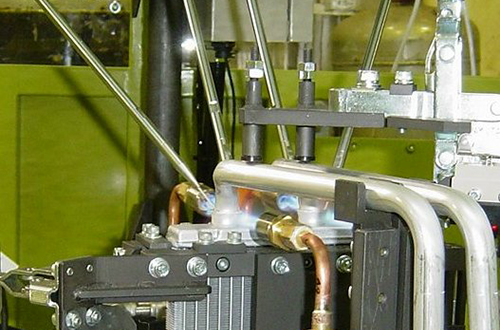

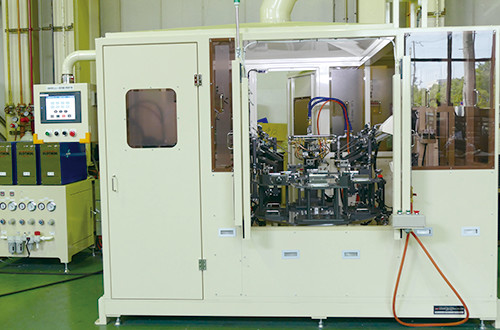

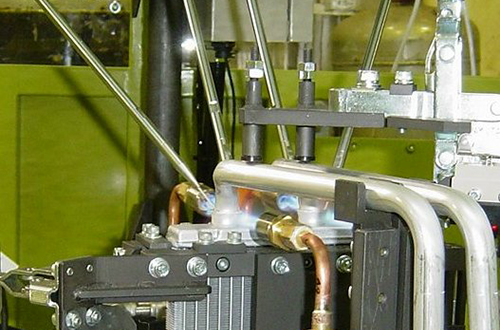

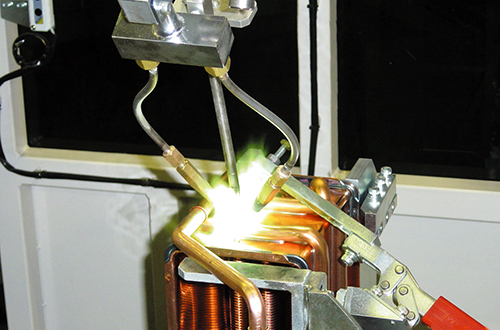

Model I

- Induction brazing machine

- Parts are brazed by induction heating via high-frequency induction coil

- Large HMI Touch Panel

- High frequency oscillator

- Current transformer

- Application-specific designed custom induction heating coil

- A part is loaded in the fixture. The heating coil shifts to heating position around the part for brazing

- Specification of Equipment (Standard)

- PRODUCT

MACHINERY DEPARTMENT

MATERIAL DIVISION